7 Essential Poultry Housing Requirements for Healthy Birds

Discover essential poultry housing requirements for healthy, productive birds. From space needs and ventilation to lighting and safety measures, learn how to create the perfect home for your chickens, ducks, and turkeys while meeting industry standards and regulations.

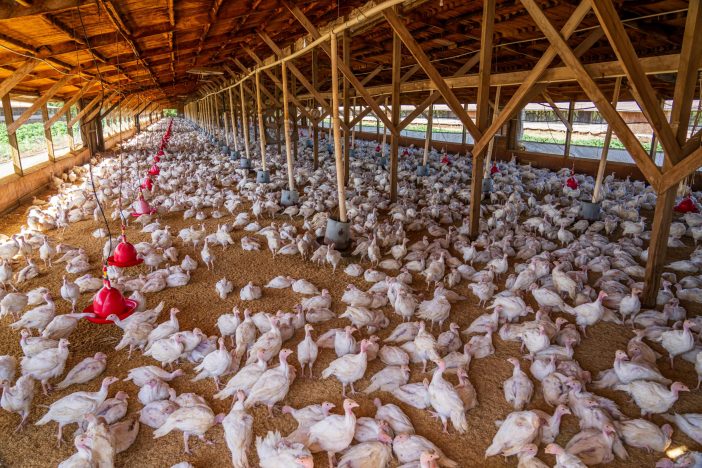

Providing proper housing for your poultry is crucial for their health well-being and optimal egg production. Whether you’re raising chickens ducks or turkeys your birds need a secure shelter that protects them from predators harsh weather and disease while giving them enough space to thrive.

The right poultry housing setup can mean the difference between a successful flock and constant challenges – from adequate ventilation and lighting to appropriate nesting boxes and roosting areas these essential requirements help ensure your birds stay comfortable and productive all year round.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Basic Poultry Housing Requirements

Proper housing infrastructure serves as the foundation for healthy poultry development.

Minimum Space Requirements Per Bird

- Layer hens need 2-3 square feet per bird in enclosed coops

- Meat chickens require 3-4 square feet each

- Turkeys demand 6-8 square feet per bird

- Free-range areas should provide 8-10 square feet per chicken

- Broody hens need 4 square feet of private nesting space

- Roosters require additional space at 4-5 square feet each

Essential Ventilation Standards

- Install 1 square foot of ventilation per 10 square feet of floor space

- Position vents high on walls to prevent direct drafts

- Add adjustable windows on opposite walls for cross-ventilation

- Ensure 2-3 air changes per hour in winter

- Increase to 5-6 air changes per hour during summer

- Keep ammonia levels below 25 parts per million

Lighting Guidelines

- Chicks need 20-22 hours of light for first week

- Reduce to 16 hours for weeks 2-8

- Layer hens require 14-16 hours daily for optimal egg production

- Maintain 5-10 foot candles of light intensity

- Position lights 7 feet above floor level

- Use warm LED bulbs rated at 2700K color temperature

Choosing the Right Housing Structure Type

poultry housing solutions” class=”wp-image-168″/>

poultry housing solutions” class=”wp-image-168″/>Your choice of poultry housing structure directly impacts bird health productivity and operational costs. Here’s what you need to know about each system:

Free-Range Housing Systems

Free-range systems provide birds with outdoor access during daylight hours along with indoor shelter. You’ll need a minimum of 43 square feet per bird outdoors plus 2 square feet indoors. These systems promote natural behaviors but require predator-proof fencing and weather protection.

Deep Litter Housing Systems

Deep litter systems use 8-12 inches of absorbent material like wood shavings or straw on concrete floors. The litter breaks down naturally creating beneficial microorganisms while reducing cleaning frequency. This system works best with 2-3 square feet per bird and proper ventilation to manage moisture.

Battery Cage Systems

Battery cages house individual birds in wire enclosures typically stacked in rows. Each hen needs 67-86 square inches of usable space with access to feed water and automated egg collection. While efficient for commercial operations these systems limit natural behaviors and face increasing regulation.

Organic Housing Requirements

Organic housing mandates 1.8 square feet per hen indoors plus 4 square feet of outdoor access. You’ll need natural lighting roosts and nests made from approved materials. Systems must allow birds to dust bathe forage and exercise while meeting USDA organic certification standards.

Creating Optimal Environmental Conditions

Maintaining precise environmental conditions in your poultry house directly impacts bird health productivity & welfare.

Temperature Control Methods

Install thermal sensors at bird level to monitor temperatures consistently. Keep brooder temperatures at 95°F for day-old chicks reducing by 5°F weekly until reaching 70-75°F for adults. Use radiant heaters in winter & cooling pads with tunnel ventilation in summer. Position thermostats away from direct heat sources or drafts for accurate readings.

Humidity Management

Maintain relative humidity between 50-70% using automated monitoring systems. Install moisture-resistant exhaust fans to remove excess humidity in winter. Add evaporative cooling cells for summer months when humidity drops below 50%. Monitor litter conditions daily as they indicate moisture levels.

Air Quality Standards

Install carbon dioxide monitors to keep levels below 3000 ppm. Position ammonia sensors at bird height maintaining levels under 25 ppm. Use minimum ventilation rates of 0.1-0.2 cfm per pound of bird weight. Clean or replace air filters monthly to prevent dust accumulation & maintain proper airflow.

Installing Essential Housing Equipment

Proper equipment installation ensures your poultry’s comfort health and productivity. Here’s what you’ll need to set up:

Feeding and Watering Systems

Install automatic feeders at bird shoulder height with 2-3 inches of feeding space per bird. Mount nipple drinkers or waterers 6 inches above floor level providing one water source per 8-10 birds. Position equipment along walls to maximize open floor space while ensuring easy access for cleaning and refilling.

Nesting Boxes and Perches

Mount nesting boxes 2 feet above the floor with one box per 4-5 hens. Install wooden perches 18-24 inches high allowing 8-10 inches of roosting space per bird. Ensure perches are at least 12 inches from walls with rounded edges to prevent foot injuries.

Waste Management Solutions

Install dropping boards beneath perches to collect waste. Use deep litter systems with 8-12 inches of absorbent material like pine shavings or straw. Place removable collection trays under wire mesh floors in raised coops. Consider automated scraping systems for larger operations.

Implementing Safety and Biosecurity Measures

Protecting your poultry from external threats requires comprehensive security protocols and disease prevention strategies.

Predator Protection Systems

Install 1-inch galvanized mesh wire buried 12 inches deep and extending 48 inches high around coops to deter digging predators. Use motion-activated lights overhead deterrent systems that activate when predators approach. Secure all windows doors with predator-proof latches and reinforce weak points with hardware cloth.

Disease Prevention Infrastructure

Install footbaths containing EPA-approved disinfectant at all entry points. Maintain separate storage areas for clean bedding feed and contaminated materials. Use dedicated boot scrubbers and protective clothing stations at transition zones. Position hand sanitizing stations at key traffic points throughout the facility.

Access Control Requirements

Establish designated clean and dirty zones with clear signage and physical barriers. Restrict visitor access to essential personnel only requiring protective gear changes between zones. Set up a log system to track all facility entries documenting time date and purpose of visits.

Managing Seasonal Housing Adaptations

Your poultry housing needs to adapt to changing weather conditions to maintain optimal bird health and productivity throughout the year.

Winter Housing Modifications

Install draft shields along windows and doors to prevent cold air infiltration while maintaining ventilation. Add extra bedding depth to 12 inches for better insulation. Cover mesh windows with clear plastic panels but leave a 2-inch gap at the top. Install heat lamps 18 inches above roosting areas when temperatures drop below 20°F.

Summer Cooling Solutions

Mount industrial fans to create cross-ventilation at 3-foot intervals. Install misting systems that activate at 85°F with nozzles placed 6 feet above ground. Add reflective roof coating to reduce heat absorption by 30%. Create shaded outdoor areas using 70% shade cloth mounted 7 feet high.

Weather Protection Features

Build 45-degree roof overhangs extending 24 inches to shield against rain and snow. Install gutters with downspouts directed away from the foundation. Add storm shutters to windows that close automatically at 20 mph winds. Use water-resistant siding with vapor barriers to prevent moisture penetration.

Meeting Regulatory Compliance Standards

Navigate complex poultry housing regulations by understanding federal state and local requirements that govern commercial organic and welfare standards.

Commercial Housing Regulations

- Follow USDA guidelines requiring a minimum space of 67 square inches per laying hen in conventional cage systems

- Maintain documentation of daily temperature humidity and ventilation readings

- Install proper waste management systems meeting EPA requirements for runoff control

- Comply with state-specific facility registration and licensing requirements

- Ensure feed storage areas meet FDA safety standards

Organic Certification Requirements

- Provide 1.8 square feet of indoor space and 4 square feet of outdoor access per bird

- Use only approved organic materials for construction and bedding

- Install natural lighting sources covering at least 50% of the indoor area

- Maintain detailed records of organic feed housing and healthcare practices

- Schedule annual inspections with USDA-accredited certifying agents

Animal Welfare Standards

- Follow United Egg Producers guidelines for beak trimming ventilation and handling

- Provide enrichments like dust baths perches and scratch areas

- Maintain ammonia levels below 25 ppm with proper ventilation

- Ensure birds have continuous access to clean water and appropriate feed

- Conduct daily health inspections and maintain mortality records

Frequently Asked Questions

How much space does each chicken need in a coop?

Layer hens need 2-3 square feet per bird inside the coop, while meat chickens require 3-4 square feet. For free-range areas, provide 8-10 square feet per chicken outdoors. Roosters need slightly more space at 4-5 square feet each.

What are the lighting requirements for laying hens?

Laying hens need 14-16 hours of light daily for optimal egg production. Chicks require more light initially, with 20-22 hours in their first week, reducing to 16 hours for weeks 2-8.

How much ventilation is needed in a poultry coop?

Provide 1 square foot of ventilation per 10 square feet of floor space. Maintain 2-3 air changes per hour in winter and 5-6 in summer. Vents should be positioned high on walls to avoid drafts.

What’s the ideal setup for nesting boxes?

Mount nesting boxes 2 feet above the floor, with one box serving 4-5 hens. This setup provides adequate privacy for laying and makes egg collection convenient while preventing floor laying.

What temperature and humidity levels are best for poultry?

Adult birds thrive in temperatures between 65-75°F, while chicks need warmer temperatures. Maintain relative humidity between 50-70% for optimal health and comfort.

How do I protect my poultry from predators?

Install 1-inch galvanized mesh wire buried 12 inches deep and extending 48 inches high around coops. Add motion-activated lights and secure locks. Ensure all openings are properly sealed at night.

What are the basic feeding and drinking requirements?

Position automatic feeders at bird shoulder height with 2-3 inches of feeding space per bird. Install one water source per 8-10 birds, mounted 6 inches above the floor using nipple drinkers or waterers.

What type of flooring is best for a poultry coop?

Deep litter systems using 8-12 inches of absorbent material on concrete floors work best. This system allows beneficial microorganisms to develop and reduces cleaning frequency while providing comfort for the birds.

How do I prepare the coop for different seasons?

In winter, install draft shields, add extra bedding, and use heat lamps when needed. For summer, mount industrial fans, install misting systems, and create shaded areas outdoors.

What are the requirements for organic poultry housing?

Organic housing requires 1.8 square feet per hen indoors and 4 square feet outdoors. Natural lighting, approved materials for roosts and nests, and compliance with USDA organic certification standards are mandatory.