10 Standard Poultry House Dimensions for Maximum Farm Efficiency

Discover the industry-standard dimensions for poultry houses, from broiler to layer facilities. Learn optimal space requirements, ventilation specs, and cost considerations to maximize bird health and farm profitability in this comprehensive guide.

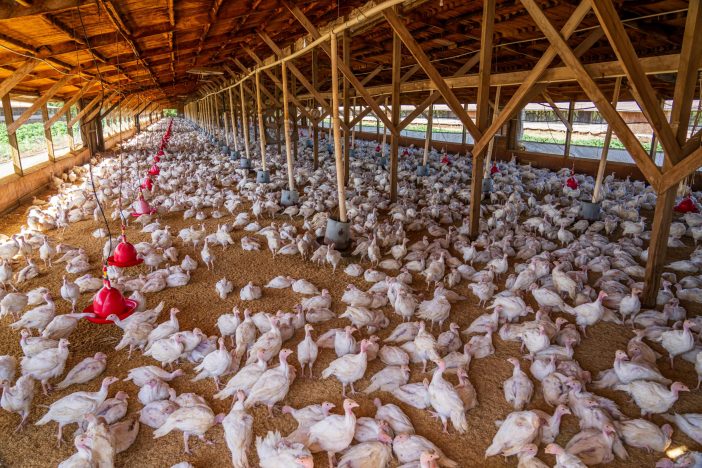

Building the right-sized poultry house is crucial for your birds’ health productivity and your farm’s profitability. Whether you’re planning to raise broiler layers or free-range chickens the dimensions of your poultry house will directly impact ventilation feed efficiency and overall flock management.

Today’s commercial poultry houses typically follow standardized measurements that have been proven effective through years of industry experience and research. We’ll explore the standard dimensions for different types of poultry operations and help you understand how to choose the perfect size for your specific needs.

Disclosure: As an Amazon Associate, this site earns from qualifying purchases. Thank you!

Understanding Poultry House Dimensions and Standards

Standard poultry house dimensions follow industry-tested specifications based on flock size capacity. A typical commercial broiler house measures 40-50 feet wide by 400-600 feet long providing 16000-30000 square feet of space. Layer houses generally require 20000-25000 square feet for 20000 birds.

| House Type | Width (ft) | Length (ft) | Total Area (sq ft) | Bird Capacity |

|---|---|---|---|---|

| Broiler | 40-50 | 400-600 | 16000-30000 | 20000-40000 |

| Layer | 40-50 | 500-600 | 20000-25000 | 15000-20000 |

| Breeder | 40-45 | 400-500 | 16000-22500 | 10000-15000 |

These dimensions maximize space efficiency while maintaining proper ventilation requirements of 0.5-2.0 cubic feet per minute per bird depending on age size.

Key Factors That Determine Poultry House Size

Several critical elements influence the dimensions of your poultry house to ensure optimal bird health and production efficiency.

Bird Species and Housing Requirements

Different poultry species need varying space allocations. Broilers require 0.8-1.0 square feet per bird while layers need 1.5-2.0 square feet. Turkeys demand more space at 3.5-4.0 square feet per bird due to their larger size. These requirements directly impact your building’s total square footage calculations.

Production System Type

Your chosen production method shapes space requirements. Free-range systems need additional indoor space at 1.5x the standard allowance plus outdoor access. Cage systems optimize vertical space with 67-76 square inches per layer while deep litter systems require 1.2 square feet per bird for proper movement.

Local Climate Conditions

Climate dictates structural dimensions for temperature control. Hot climates need higher ceilings at 12-15 feet for heat dissipation while cold regions benefit from 8-10 foot heights to retain warmth. Wide houses (45-50 feet) work better in temperate zones while narrow designs (35-40 feet) suit extreme climates.

Standard Dimensions for Different Poultry Operations

Broiler House Measurements

Standard broiler houses measure 40-50 feet wide by 400-600 feet long providing 16,000-30,000 square feet of floor space. These dimensions accommodate 20,000-40,000 birds with 0.8-1.0 square feet per bird. Ceiling heights typically range from 8-10 feet at the sidewalls to 12-14 feet at the peak for optimal ventilation.

Layer House Specifications

Commercial layer houses require 20,000-25,000 square feet to house 20,000 laying hens efficiently. Modern facilities use vertical cage systems with 6-8 tiers reaching heights of 18-20 feet. Free-range operations need additional space with indoor areas measuring 30-40 feet wide by 400-500 feet long plus outdoor access.

Breeder House Dimensions

Breeder houses average 45-55 feet in width and 400-500 feet in length accommodating 10,000-15,000 breeders. These facilities require 2.0-2.5 square feet per bird to support proper mating behavior. Standard ceiling heights range from 10-12 feet at the sidewalls with a 16-18 foot peak for ventilation.

Space Requirements per Bird Type

Different poultry types require specific space allocations based on their size purpose weight movement patterns.

Commercial Broilers

Commercial broilers need 0.8-1.0 square feet per bird in controlled environments. Fast-growing meat birds require adequate space to prevent overcrowding stress reduced feed efficiency lower growth rates. Free-range operations should provide 2-3 square feet per bird indoors plus 10 square feet of outdoor access.

Layer Hens

Layer hens in conventional cage systems require 0.6-0.7 square feet per bird. Cage-free systems demand 1.5-2.0 square feet of indoor floor space per hen. For optimal egg production provide 4-5 square feet per bird in free-range setups plus 8-10 square feet of outdoor space.

Breeding Stock

Breeding birds need 2.0-2.5 square feet per bird in controlled environments. Heavy breeds require more space at 3.0-3.5 square feet per bird. Males need additional space at 3.5-4.0 square feet each to maintain proper breeding ratios nest access fertility rates.

Essential Floor Space Calculations

Proper floor space calculation ensures optimal bird health productivity while maximizing facility efficiency.

Density Guidelines

Calculate floor space using these standard density ratios:

- Broilers: 0.8-1.0 sq ft per bird in controlled environments

- Layers: 0.6-0.7 sq ft per bird in cages 1.5-2.0 sq ft in cage-free systems

- Breeders: 2.0-2.5 sq ft per bird with additional space for males

- Free-range: Add 8-10 sq ft outdoor space per bird to indoor requirements

- Day-old chicks: 0.25 sq ft per bird

- Weeks 1-4: 0.5 sq ft per bird

- Weeks 5-8: 0.75 sq ft per bird

- Adult birds: Follow standard density guidelines per type

- Reduce density by 15% in hot climates

Structural Components and Measurements

Standard poultry house construction requires specific measurements to optimize bird performance ventilation efficiency.

Height Requirements

Modern poultry houses need 8-10 feet sidewall height for conventional setups with 12-16 feet at the peak. Layer operations using vertical cage systems require taller structures reaching 18-20 feet to accommodate 6-8 tiers. Hot climate zones benefit from increased ceiling heights of 14-18 feet for better air circulation.

Width Specifications

Standard commercial poultry house widths range from 40-50 feet for broiler operations and 45-55 feet for breeder facilities. Wider spans of 50-60 feet suit cage-free layer houses to accommodate interior equipment nests feeders while maintaining proper bird density ratios.

Length Recommendations

Commercial poultry house lengths typically span 400-600 feet for optimal operational efficiency. Smaller operations can function effectively with 200-300 foot lengths while maintaining proper width ratios. Consider 50-foot increments when planning length expansions to match standard equipment specifications.

Ventilation and Space Management

Proper ventilation and space management are crucial for maintaining optimal health conditions in poultry houses while maximizing production efficiency.

Air Flow Requirements

A standard poultry house requires 0.5-1.0 cubic feet per minute (CFM) of air exchange per pound of bird weight in winter and 1.5-2.0 CFM in summer. Your ventilation system should provide 6-8 complete air exchanges per hour for birds under 4 weeks old and 10-12 exchanges for mature birds. Install fans every 25-30 feet along sidewalls to maintain consistent airflow throughout the house.

Temperature Control Zones

Create distinct temperature zones by dividing your poultry house into brooding (95°F for chicks) and growing areas (75-85°F for adults). Install minimum ventilation fans every 40 feet to maintain a 10-15°F temperature gradient from end to end. Use tunnel ventilation in houses longer than 300 feet to prevent heat buildup at the exhaust end.

Building Codes and Regulations

Poultry house construction must comply with specific building codes and regulations to ensure safety health standards and environmental protection.

Local Zoning Requirements

You’ll need to obtain permits from your local zoning board before constructing a poultry house. Most municipalities require setbacks of 50-100 feet from property lines and 200 feet from residential areas and compliance with maximum building height restrictions of 20-25 feet. Check with your county extension office for specific agricultural zoning ordinances.

- Concrete foundations with 6-inch thickness

- Fire-resistant materials for walls and roofing

- Minimum 16-foot service door width

- Emergency power backup systems

- Perimeter security fencing at least 6 feet high

Cost Considerations for Different Sizes

Understanding the financial implications of different poultry house sizes helps optimize your investment and operational success.

Construction Expenses

Initial construction costs vary significantly based on size with typical expenses ranging from $7-12 per square foot for basic structures to $22-28 for fully automated facilities. A standard 40′ x 400′ broiler house costs $180,000-250,000 while a 50′ x 500′ house requires $250,000-350,000. Labor installation equipment & materials increase proportionally with size but offer economies of scale for larger facilities.

Operational Efficiency

Larger houses (40,000+ birds) reduce per-bird costs through shared equipment infrastructure & labor optimization. A 40′ x 400′ house requires $1.80-2.20 in operating costs per bird annually while 50′ x 500′ houses lower this to $1.50-1.80 through improved feed conversion ratios & automated systems. Utility expenses typically decrease 15-20% per bird in bigger facilities.

| House Size | Basic Cost | Automated Cost |

|---|---|---|

| 40′ x 400′ | $180,000 | $250,000 |

| 50′ x 500′ | $250,000 | $350,000 |

| Cost/sq ft | $7-12 | $22-28 |

Choosing the Right Size for Your Operation

Building the right-sized poultry house is crucial for your operation’s success. Whether you’re planning a broiler layer or breeder facility the dimensions you choose will directly impact your birds’ health and your farm’s profitability.

Remember that your local climate regulations and specific production goals should guide your sizing decisions. You’ll find that investing time in proper planning and following industry-standard measurements will lead to better outcomes for both your birds and your bottom line.

Take the next step by consulting with local agricultural extension services or poultry housing experts. They’ll help you develop a customized plan that meets your specific needs while adhering to proven industry standards.

Frequently Asked Questions

What is the standard size for a commercial broiler house?

A typical commercial broiler house measures 40-50 feet wide by 400-600 feet long, providing 16,000-30,000 square feet of space. This size can accommodate 20,000-40,000 birds, with each bird requiring 0.8-1.0 square feet of space.

How much space does a layer house need?

Layer houses typically require 20,000-25,000 square feet to house 20,000 birds. They utilize vertical cage systems with 6-8 tiers, reaching heights of 18-20 feet. In cage systems, each bird needs 0.6-0.7 square feet, while cage-free systems require 1.5-2.0 square feet per bird.

What are the space requirements for breeder houses?

Breeder houses average 45-55 feet in width and 400-500 feet in length, accommodating 10,000-15,000 breeders. Each bird requires 2.0-2.5 square feet of space. Standard ceiling heights range from 10-12 feet at sidewalls to 16-18 feet at the peak.

How much outdoor space is needed for free-range operations?

Free-range operations should provide 2-3 square feet of indoor space and 10 square feet of outdoor space per bird. Indoor areas typically measure 30-40 feet wide by 400-500 feet long, with additional outdoor access areas.

What are the ventilation requirements for poultry houses?

Poultry houses need 0.5-1.0 cubic feet per minute (CFM) of air exchange per pound of bird weight in winter and 1.5-2.0 CFM in summer. The system should provide 6-8 complete air exchanges hourly for young birds and 10-12 exchanges for mature birds.

How much does it cost to build a poultry house?

Construction costs range from $7-12 per square foot for basic structures to $22-28 for fully automated facilities. A standard 40′ x 400′ broiler house costs between $180,000 and $250,000, while a 50′ x 500′ house ranges from $250,000 to $350,000.

What are the space requirements for different age groups of birds?

Day-old chicks need 0.25 square feet, birds in weeks 1-4 require 0.5 square feet, and those in weeks 5-8 need 0.75 square feet. Adult birds’ space requirements vary by type, with commercial broilers needing 0.8-1.0 square feet and breeders requiring 2.0-2.5 square feet.

What temperature zones are needed in a poultry house?

Poultry houses should have separate zones for brooding (95°F for chicks) and growing areas (75-85°F for adults). A temperature gradient of 10-15°F should be maintained, with minimum ventilation fans installed every 40 feet.